In this tutorial we will walk through the overall process of how to build a lean to shed. Building a lean to shed is fun and the project will teach you all sorts of new skills that you can use to build other structures like man caves, she sheds, backyard offices, storage sheds, and other outbuildings. This is a 10×10 shed with a single pitch roof. Let's dive into more details about the shed build below. If you are interested in getting the plans, they can be purchased here.

Shed Building Video

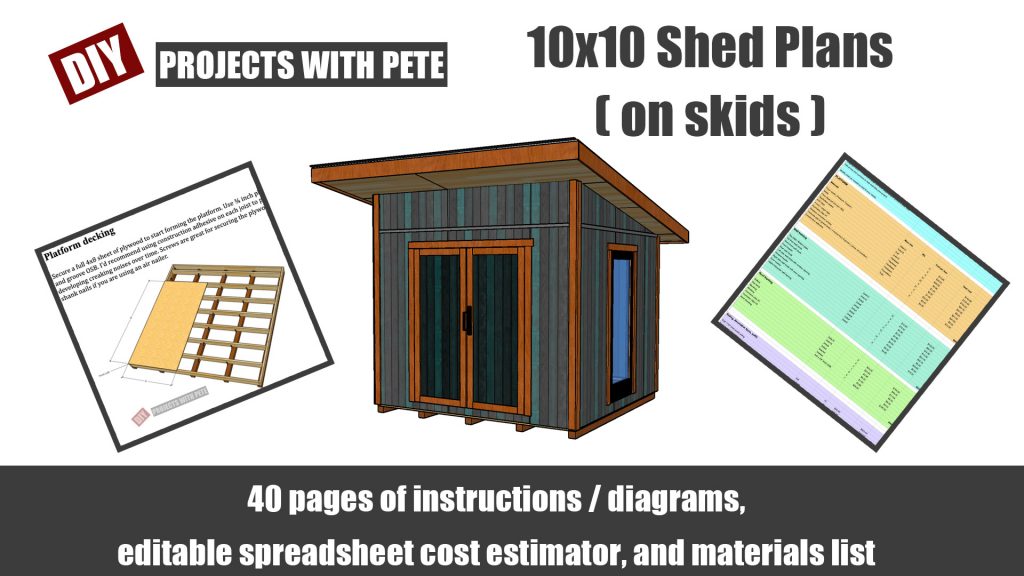

DIY Pete's 10×10 Shed Plans

If you would like to purchase plans to help guide you through the process, they can be downloaded here. The plans come with a materials list and editable spreadsheet to help you calculate up to date costs.

Plan your shed

Determine how large you want to build your shed. Check with your homeowners association or city to see if there are permits or size restrictions prior to building. Oftentimes if you build it on skids it will be classified as a temporary structure. If built on skids, I'd recommend placing it on a 4 inch gravel pad once complete so it is level and has proper drainage. You could do a concrete pad, concrete blocks, or sono tubes if you'd prefer.

Sheds come in all shapes and sizes. One of the first sheds I ever built was about 6 years ago at my first house. Here is a link with more information about the lean to shed which was about 7 feet wide by 4 feet deep.

Purchase materials

The first step of the project was to come up with a design and then to purchase materials. I chose to build a 10 foot by 10 foot shed with a single pitch slope. This is often referred to as a lean to style shed. This style of shed has a modern look and is pretty straightforward to build. I purchased most of the lumber at either Home Depot or Kenyon Noble in my town.

How much does it cost to build a 10×10 lean to shed?

There are many variables that will affect the cost to build a shed. At the time I built my shed in September of 2021 the cost for the wood was about $1850. The cost for the supplies ( shingles, window, nails, hardware, etc ) came to $760. The total cost to build my 10×10 lean to shed was $2610. This does not include labor.

How long does it take to build a 10×10 lean to shed?

Great question. This will vary depending on your skill level, amount of help, and time you are able to work on it. I would say it should take about 7-12 work days if you keep at it. Otherwise it could be done on the weekends over the course of a month or two. If you are a well skilled DIY'er and have plans, I think it could be built faster. If you are more of a beginner, the project could obviously take more time. The great thing is that you will learn so much from this project and your new skills can be used to build other structures!

Building the skid foundation and platform

I chose to build the shed using pressure treated 2×6 boards for the joists. The joists are spaced every 16 inches on center. Underneath the joists are five 4×4 pressure treated boards. These are used as skids. Skids give you the ability to move the shed. I tacked the joists to the skid at each location and then used metal brackets for additional strength. I also used some 6 inch long structural leg screws from the bottom of the 4×4 and through the joist.

The platform or shed floor

The shed floor is made of plywood. A 3/4 inch thick tongue and groove plywood is best for a floor, but due to a pandemic the price of most plywoods was way too expensive. So I opted for 23/32 CDX plywood which was half the cost at the time. I used a chalk line to mark joists and to make straight lines for cutting.

The lean to shed floor is 10 feet by 10 feet. The plywood is attached to the joists using nails.

Walls for a lean to shed

Framing walls for a shed goes fairly quickly and is a lot of fun. The rear wall measured about 7 1/2 feet in height.

After being built, the walls are stood up and then secured in place using framing nails. Make sure to nail into the outer joist.

Double top plates add additional strength and also provide a way to tie each wall together.

Framing for the rough opening of a window or door is easier than you may think. If you look at framing diagrams online you'll be able to figure out how to do it. I used 2×6 boards for the header.

For my shed, the walls were all built to the same height. As you can see, I used 2 jack studs ( trimmers ) on each side under the header for the doors.

Next, I added a smaller wall to create more height at the front of the shed. I wasn't originally sure what would look nice for the pitch, so I built the smaller wall and then laid a rafter up top to get a look. Next time I would simply build the front wall with 2x4x10 boards so it wasn't two separate walls to tie together. This actually was super easy to do, but using just one wall is probably a better way to do it. I ended up going with about a 1.5/12 pitch.

Rafters for a lean to shed

The rafters are made out of 2×6 boards. They overhang the front a couple feet and the back about 10 inches. A birds mouth cut was made at the front and back of each rafter so the rafter rests flat on the top plate. The rafters were secured every 24 inches on center using hurricane clips.

Sub facia was added to the front, back, and sides. This ties the rafters together.

Siding

An angled sidewall and blocking was added beneath the rafters so the siding would be able to secure to the upper part of the wall. In the photo below, Pete is adding 4×8 sheets of siding to the shed. 2 inch long nails in a coil nailer are used to secure it to the studs.

Roofing

I used 7/16 inch plywood for the roofing material. OSB is another material that could be used.

Paint the shed

I rolled on the first coat of paint. I'd recommend using a roller with longer than 1/2 inch or more nap so the paint goes into the grooves of the siding. I used a dark grey or charcoal color to match my other shed. It took 2 coats total which was about 1 1/2 gallons of paint.

DIY Pete Stain and Paint Colors

I've had a lot of DIY'ers ask about the colors I used. So I've added these photos of the cans to the post. For the paint, I used the Sherwin Williams paint on the left. It is an Iron Gray color, but they don't have it in their system so they did a custom match. If you don't want to go to Sherwin Williams you can simply look for a charcoal colored paint.

For the stain I used Olympic Elite in the Atlas Cedar color. I used semi-transparent. You can take a photo of the paint code or print off the picture if you want to have Sherwin Williams match it perfectly.

Facia board

1×8 boards were used for the facia. I stained all sides prior to installing it.

Shingles and underlayment

Drip edge was first nailed to the back side of the shed, then an underlayment was rolled out and nailed to the plywood with capped nails. I used a synthetic underlayment, but tar paper is another option and it is cheaper. Drip edge was then installed on the sides as seen in the photo below.

I used a starter roll of shingles and then started nailing down the shingles. It took 5 boxes to do the entire roof.

Shed doors

The doors were framed out of 2×4 boards. I used pocket holes and screws to connect the boards. Next, I attached OSB to the backside of the doors to increase strength and prevent warping. Finally, siding was attached to the frontside.

Shed window

I had an old white vinyl window left over from another project and decided to paint it black. To do this, I first took the glass panes out of the window frame. Next, I sanded the white vinyl with 400 grit sandpaper so paint would bond better to it. I then used rubbing alcohol to clean the window prior to applying a black exterior grade spray paint meant to be used on plastic and vinyl. Once dry, I reinstalled the window panes using a clear silicone. You could also use glazing tape.

Trim for a lean to shed

Oftentimes an engineered trim with a wood pattern is used on sheds. There was a shortage of it at the time the shed was built, so I decided to use 1×4 pine boards and to use an oil based exterior stain on them. I used a large brush to stain all sides of each board. I used 1/2 inch thick plywood for the soffit. You may need to add some additional blocking prior to putting up the soffit.

Paint was applied to the doors and the trim was laid out.

Install doors and hardware

I used three six inch hinges to install each shed door. Additional hardware including handles, latches, and barrel bolts were also added.

How to organize a shed and build shelves

The next step before loading the shed with stuff is to build shelves and install shed organization items. Here is a link to a youtube video I made showing how to build a shelf loft, shelves, and racks for tools https://youtu.be/Ddrg6zPl2Q8. It can also be watched below.

https://youtu.be/Ddrg6zPl2Q8

Start using your new shed!

I hope the How to Build a Lean To Shed tutorial was helpful and that the video helps guide you through the basic process. If you have questions or need help please comment below or reach out on instagram.

Other shed projects and warming house

A big reason I built this shed was to practice my skills and to see what I liked and disliked about the design. My plan is to build a 12×20 foot ice rink warming house for our backyard hockey rink next! You can learn more about the rink in my hockey rink post and there is a video showing how it was built as well. I will be documenting the warming house build this fall!

Please share your projects below in the comments!

I'd love to see what you come up with. Please share photos of your shed, man cave, she shed, backyard office, or other building you built below! Cheers and have fun with the project.