Favorite Tools and Supplies

My favorite tools!

On this page are links to many of the tools, equipment, and supplies I use out in the shop. Some of the links are affiliate links, meaning I get a small commission for recommending the tools to you. If you do end up purchasing through the link I’d really appreciate it.

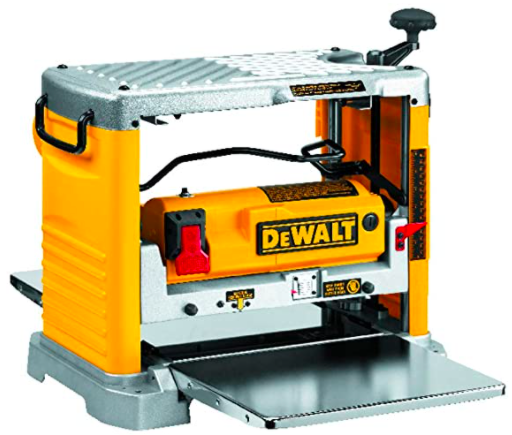

I'm not sponsored or directly affiliated with Dewalt, but I just like their high quality. I've collected their tools over the years and they're super heavy-duty with a great interchangeable battery system too. I'm linking to mostly battery powered tools because they are just so darn handy compared to corded tools. However, corded tools can be the less expensive option if you're on a tight budget.

Drills

A good drill is going to be one of your best friends in the shop. Drills drive in screws (and reverse them back out), pre-drill holes so the wood won't crack, cut big holes with a hole saw, and more. A nice drill has plenty of power and can adjust the torque and speed of drilling. And yes, there are several types of drills that look very similar but function very differently!

Saws

There are many different types of saws to cut wood and other materials. It can be overwhelming! I'll try to describe their uses below so you get the right tool for the job.

Sanders and routers

Building your project is one thing, but finishing it is another thing. Finishing means sanding it smooth and adding a protective coat like a stain, polyurethane, or paint.

Sanding rough edges and splinters into a smooth, finished project can take quite a bit of time, especially if you choose to progress through a few different levels of sandpaper grit.

Routers can add intricate edges to your corners and do a few other useful tricks.

This bigger sander is nice for sanding smaller pieces of wood. Something that is too tough to hold onto in one hand and an orbital in the other, use the belt sander for. A great example is all the 2x4 blocks for giant Jenga!

Jigs and clamps

Jigs and clamps help to get things just right. According to the dictionary, a jig is "A device that holds a piece of work and guides the tools operating on it." A jig can be a specific jig tool, or it can be a block clamped to your miter saw as a stop so that you cut every piece the same size.

Metal working tools

Metal working is another set of tools that mostly don't overlap with woodworking tools. A drill is about the only one from the tools listed above. Metal tools use a lot of heat, emitting sparks and metal dust in your garage.

Welding is the main way and the probably the strongest way for metal joinery. It is kind of an intense process and takes practice for your welds to look good! Pay attention to the voltage of your welder—if you need the usual 110v or can go bigger with 220v. There are also different types of welders for different types of metals—mainly, MIG and TIG. Be sure to get safety equipment too!

Having a big torch in the garage can be helpful for a number of things (like smoothing out your hockey rink!). For metal work, it helps create a cool looking patina when combined with stain chemicals.

Concrete tools

Here are a few tools for finishing the concrete with a polisher. There are also a few basic tools like a bucket and a mixer to pick up, too. I have information on the different concrete mix types on my FAQ page.

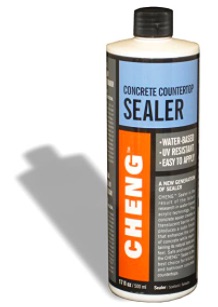

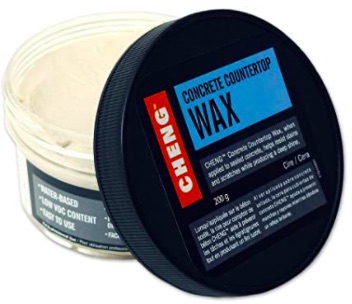

After the concrete is polished, you'll want to seal it to protect it. I like the Cheng brand. First you seal it with this product, then apply a final wax coat.

Add this as your last step to make sure your concrete looks great for a long time. The sealer and wax help prevent stains, and they're food-safe, so they're good for kitchen counters.

Yard tools

I've got a few acres in the foothills of the Rocky Mountains, so there's always yard work to do. Having the right tool for the job is just as important in the backyard as it is in the shop.

An electric chainsaw might seem a little strange but they're very convenient and can get most jobs done around the yard. I have a whole review and comparison to other gas saws in this video here.

If you've made your own backyard hockey rink like I have, you'll figure out that you need a big shovel. This 4' wide plastic shovel works great on ice, the deck, or the driveway!

Safety gear

Don't forget your safety gear! According to my brother, there's a saying in the motorcycle world: ATGATT, or All The Gear All The Time. I try to follow that for working in the shop, too!

I use my hands a lot and so keeping them protected is important. I have lots of different gloves for different types of jobs. But for basic shop work, like moving lumber around, I like a synthetic top of glove with leather palm, and an elastic band around the wrist—instead of a velcro band to take on and off.

If you're going to be welding, you absolutely need a helmet. The bright light of welding will burn your eyes pretty quickly, so modern helmets have a special lens that blocks out the bad rays. The auto-darken feature is a game changer, too, so that you can still see to get set up, then it automatically gets dark when the sparks start flying.