I needed a new coffee table for the living room and this design fit the bill perfectly. I came across a table from Ana-White.com that I loved, but modified it a bit because I wanted a breadboard style top. To see her plans click here. The difference between the table in this post is that I cut the top pieces to 41″ (vs 52″) and added the 2×6 pieces to each end, making it come to 52″ with a breadboard style top.

Level – Beginner to Intermediate – The hardest part is cutting the angled pieces

Lumber Cost – $45.00 Additional costs: Screws, Sandpaper, Stain, Poly

Overall Dimmensions: 52 x 27 x 18

Tools Needed

Mitre Saw – I use a Dewalt Mitre Saw – A circular saw will work if you don't have a mitre saw

Orbital Sander

Sanding Block

Drill – I use a Dewalt

Kreg Jig – My favorite tool in the shop (Makes Pocket Holes)

Shopping List

Lumber

QTY

4 2×6 x 8 foot long Pine Boards for top

2 2×4 x 8 foot long Pine boards for legs and end supports

3 2×2 x 8 foot long Pine Boards for side stretchers

1 1×12 x 8 foot long Pine Board for lower shelf

Cut List

QTY

5 – 2×6 41″ long for top

2 – 2×6 29″ for breadboards – Trim in later step to around 27 or 27.5″

4 – 2×4 16 1/2″ long for legs

2 – 1×12 41″ for shelf

4 – 2×2 41″ side rails (upper and lower)

4 – 2×4 22 1/2″ end rails

2 – 2×2 22 1/2″ – both ends cut at 60 Degree Angle – See video for detailed instructions

4 – 2×2 11 1/4″ – 60 degree angle for outside end and 30 degree angle for inside end

1 box 2 1/2″ Kreg Screws

1 box 1 1/4″ Kreg Screws

16 – 2 1/2″ wood screws for attaching base to table top

Supplies

120 and 220 Grit sandpaper for Orbital Sander

400 Grit sandpaper for sanding block

Semi-Gloss Polyurathane

Vinegar/Steel Wool – Optional for a distressed finish

Stain – I used Walnut Minwax

Couple Brushes

Complete Plans from Ana-White.com

Step 1.

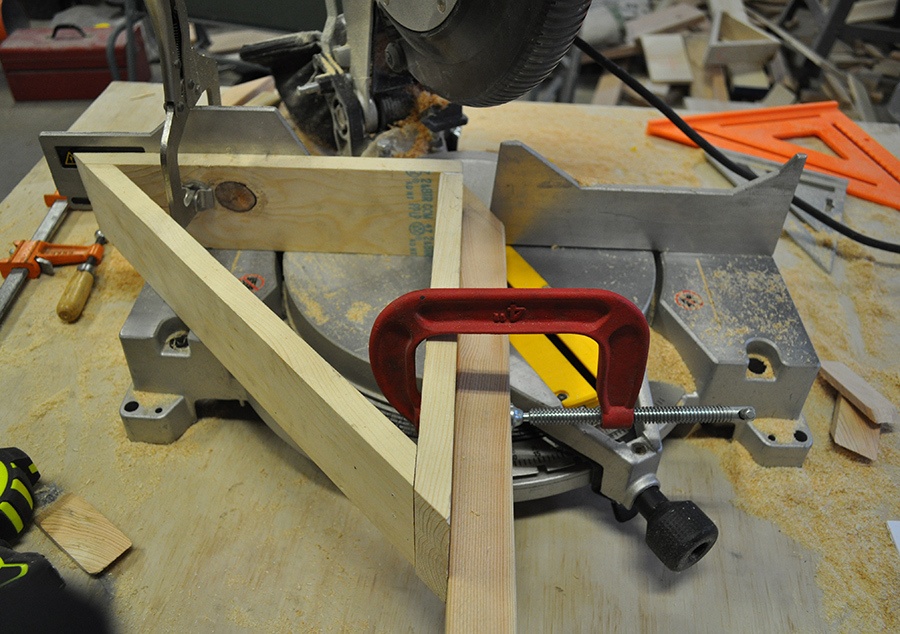

Make your cuts using a miter saw or circular saw. To cut the 60 degree angle for the “X” support you will need to make a jig similar to the one below.

To cut a 60 degree angle safely I built a jig. I simply nailed 1×4 boards together in a triangle shape. The back 1×4 rests flat on the miter saw fence. You can use the side that runs straight towards you as your new fence. Set the 2×2 board against the fence and slide it into place. Cut the angle at 30 degrees on your miter saw (it will actually cut it at 60 degrees because of your jig.

I explain the jig in this video.

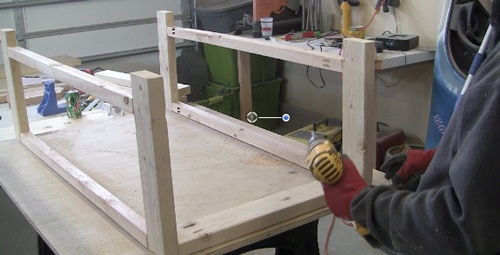

Step 2 – Assemble Sides of Table

Once your cuts are made it's time to assemble your table. For complete plans visit Ana-White.com. My table's top has been modified by doing breadboard style ends.

In this step take your 2×2 rails that are 41″ long and drill 2 pocket holes on each end using a Kreg Jig. Then take 2 1/2 kreg screws and attach the side rails to each 2×4 end piece. Measure 2 1/4 inches up from the bottom to hang your lower 2×2 rail. Note that in the photo my pocket hole screws are pointing inward. The top rail's pocket holes can face inside the table or to the ground. No matter what they won't be seen. Make sure to have the lower rail's pocket holes facing the floor so you'll be able to attach the shelf to them later.

Step 3 – Assemble Ends

Attach the 22.5″ 2×4's to each top end. Drill 2 pocket holes in each 2×4 end prior to attaching with 2 1/2 inch Kreg screws.

Step 4 – Attach lower 2×4 rails

Attach the lower 22 1/2″ 2×4 rails on each end. Measure 2 1/4 inches up from the bottom leg for placement.

Step 5 – Assemble lower shelf

Drill pocket holes to attach the 41″ 1×12 pieces to each other. Do them about every 8-10 inches. After you've attached the boards to each other using 1 1/4″ Kreg screws drill more pocket holes around the perimeter of the entire piece. It will look like the photo below.

Step 6 – Attach Shelf

I've found that it is easiest to attach the shelf by attaching the 2×2 side rails prior to connecting it to the table. To do this you'll sort of take a minor step back by removing the two lower 2×2 side rails (only 8 screws). Then drill the shelf to the 2×2's as shown below. Lift the shelf into place and attach each end of the shelf to the lower end rails using 2 1/2″ Kreg Screws. Once that is secure flip the table right side up and add the cross supports.

Step 7 – Attach cross supports

Use a nail gun or hammer and finish nails to connect the cross supports to the upper and lower 2×4 side rails. All outside angles are 60 degrees. The two shorter pieces have an inside angle at 30 degrees. The long piece is 22.5″ from outside edge to to inside edge. The 2 shorter pieces are 11 1/4″ from the inside to outer edge. Click here to see a video I made explaining the angles.

Step 8 – Assemble Table Top

Attach each 2×6 ( 41″ long ) to each other using 2 1/2″ pocket screws. The Pockets holes should be spaced about every 8 inches from each other. Use clamps to help hold boards as you attach them to each other if needed. Note that you will drill the two boards on each side into the center. Thus, the center board will not have any pocket holes drilled in it.

Step 9 – Attach Breadboard Ends

Take your breadboard ends and place them against the table top. Trim the end of the breadboards so they are flush with the width of the overall table. You will trim them down to around 27 1/4″ to 27 1/2″ most likely. Drill pocket holes so they line up to go in all 5 boards as shown below. Attach to the table top using 2 1/2″ Kreg screws.

Step 10 – Attach table top to base

Flip the table base upside down and set it on the bottom side of the table top. Center it and then screw through the bottom of the 2×2 into the table top with 2 1/2″ torque screws. Use about 3 to 4 screws on each side of the base.

Flip the table upright and you are finished assembling the table!

Part 2 – Finishing

Distress, Sand, Stain, and Finish

Watch video for detailed instructions

The first step after completely assembling the table is to sand the project. I typically use an orbital sander with 120 Grit paper. Sand the top and all sides until everything is very smooth. Don't sand too deep if you want to keep some of the wood's original texture.

Step 1 – Sand

Use an orbital sander and 120 grit sandpaper to smooth the table. Sand the top and base.

Step 2 – Distress table with tools

Mark the table up with various tools to give the table character. I like to use a hammer and a small bit to punch holes in the top that resemble worm holes (see Episode 3 -Part 2 video). You can also run a circular saw blade across to give it individual saw marks (without it being plugged in). Hammers, scraping tools, bolts, pipe wrenches, crow bars, and other tools can be used to mark up the table and give it a unique look. Make sure to keep marks random so they look natural and don't overdo the distressing!

Step 3 – Use Vinegar / Steel Wool Mixture – Optional

A vinegar and steel wool mixture will distress your wood and give it more of a barnwood look. The mixture reacts with the tannins in the wood to bring out grey and black colors. It also brings out the grain and distresses the wood. The solution works very well on fir. White pine does not react as well.

How to Make a Vinegar/Steel Wool Solution:

Put a handful of steel wool in a plastic cup and add vinegar. Do not cover the container. Let it sit for 24 hours or more. The vinegar will eventually disintegrate the steel wool. The longer it sits, the more potent the solution. To dilute simply add more white vinegar at anytime.

Once the mixture is made, simply brush the solution on the wood. It won't immediately turn colors, but over a few hours you'll notice a considerable difference. Check out the photos of my farm table project to see how well it worked using fir boards. You'll notice the fir 2×2's used in this project really took the solution well. The other boards had a little coloring and grain enhancement, but white pine doesn't have many tannins in it so it is less reactive.

Step 4 – Stain Table

Once the vinegar solution dries (or if you decided not to do the solution) you can go ahead and stain the project. First use a rag or air compressor to remove any dust from the table. Then use a clean rag to apply the stain of your choice. Don't forget to wear gloves and ventilate the area. Have a brush in your other hand to stain hard to reach areas.

The table will look similar to this when the stain is dry. I usually only apply one coat.

Step 5 – Poly the table

Use a polyurathane ( I used a Minwax Semi-Gloss ) to seal and protect the finished coffee table. Apply the 1st coat of polyurethane to the entire table. Once dry, add a second coat to the table top. I only generally do one coat of poly on the base. Once the second coat has dried take a sanding block with 400 grit sandpaper and lightly sand all areas you've poly'ed. Then take a clean damp rag to remove the dust and prepare for your final coat of poly.

Step 6 – Apply Final Coat of Poly

Use a clean rag to apply the 3rd coat of poly to the table top. Using a rag/cloth will allow the coat to go on smooth and thin. Let your table thoroughly dry and then move it into your home.

Step 7 – Sit back and Enjoy!

Relax, put your feet up, and enjoy your new table. It will be a great conversation piece that will last for years.

Please connect on facebook and post photos of your own projects. We'd love to see them! If you'd like to start a website like I did please check out my DIY Blog video about buying a domain and setting up a blog or website cheaply and easily. I used Bluehost and Wordpress to create this website!