Hey fellow Do It Yourselfer's! I have a new and exciting project to share with you that is one of my favorite projects I've ever done. I wanted to build a neat project for a patio and so I did a little brainstorming. That's when the idea came to me to build a concrete patio table with LED lights and a built-in cooler!

I've built a number of concrete counters and tables over the years. Concrete is a great medium to work with because you can make a high end table or counter any thickness, color, or shape you want. You can also embed about anything you can imagine in concrete. Concrete is also very affordable and so if you are a do it yourselfer you'll save a ton of money if you ever build your own tables or counters. Concrete counters done by a professional are commonly priced between $75 to $125 per square foot.

I've built a number of concrete counters and tables over the years. Concrete is a great medium to work with because you can make a high end table or counter any thickness, color, or shape you want. You can also embed about anything you can imagine in concrete. Concrete is also very affordable and so if you are a do it yourselfer you'll save a ton of money if you ever build your own tables or counters. Concrete counters done by a professional are commonly priced between $75 to $125 per square foot.

Complete 17 Minute LED Table Video Tutorial

This Projects Sponsors

Thanks so much to this projects Sponsors. Birddog Distributing in an amazing online store with all sorts of cool lighting products. I used their LED Strip Lights for this project. Use the coupon code: DIYPETE10 for 10% off your LED Light strip kit and tell them you are building an LED Table from DIYPETE.com!

Thanks to Quikrete for their support for this DIY project. I use Quikrete for all my concrete related projects. Their products can be found at your local home improvement store.

Overall Process

Overall Process

The detailed instructions can be found in my post on Makezine.com.

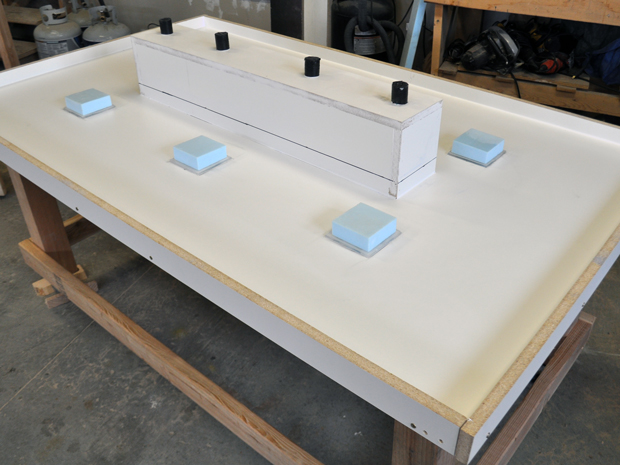

1. Build the mold out of Melamine

2. Assemble the mold

2. Assemble the mold

3. Pour the concrete

3. Pour the concrete

You may have seen some of the other videos I've created in the past about making concrete counters. I show a couple different methods of how to finish concrete. Here are the other two videos in case you are interested in starting to work with concrete.

You may have seen some of the other videos I've created in the past about making concrete counters. I show a couple different methods of how to finish concrete. Here are the other two videos in case you are interested in starting to work with concrete.

4. Let the concrete cure

Table after curing for 4 days

Table after curing for 4 days

5. Remove the mold and flip the table

5. Remove the mold and flip the table

6. Polish

6. Polish

Polish the table using a concrete wet polisher.

7. Seal the concrete

7. Seal the concrete

8. Install top on a base

8. Install top on a base

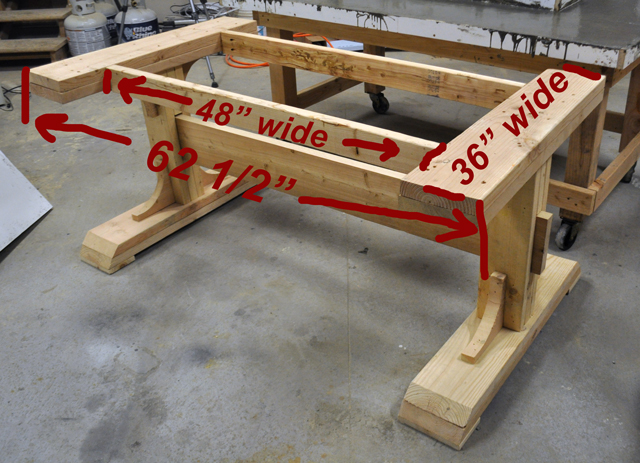

I built my table base using FREE plans from Ana White over at Ana-White.com. Here is a link to the plans and she also has a downloadable PDF. The table is modified to fit the concrete top and so the lights can be strung under the trough and the coasters. I modified Ana's plans by using a 2×10 for the stretcher and 2×8's for the horizontal end pieces. 2×6's are used for the vertical part. Here is a basic diagram of the sizing adjustments. Please use Ana's plans to help with assembling.

I built my table base using FREE plans from Ana White over at Ana-White.com. Here is a link to the plans and she also has a downloadable PDF. The table is modified to fit the concrete top and so the lights can be strung under the trough and the coasters. I modified Ana's plans by using a 2×10 for the stretcher and 2×8's for the horizontal end pieces. 2×6's are used for the vertical part. Here is a basic diagram of the sizing adjustments. Please use Ana's plans to help with assembling.

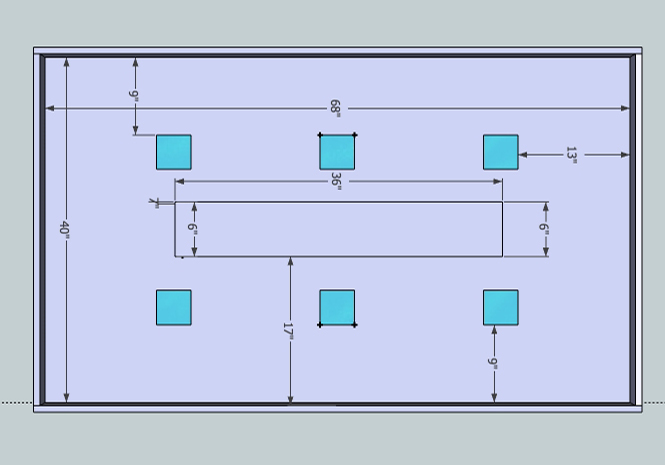

Here is a the diagram of the table top. You'll want to plan for an open area in the top part of the base no matter what type of base you build. Here is the diagram of the table top. You could use her plans to build other base styles similar to the tables I've built on this page.

Here is a the diagram of the table top. You'll want to plan for an open area in the top part of the base no matter what type of base you build. Here is the diagram of the table top. You could use her plans to build other base styles similar to the tables I've built on this page.

9. Add LED Lights!

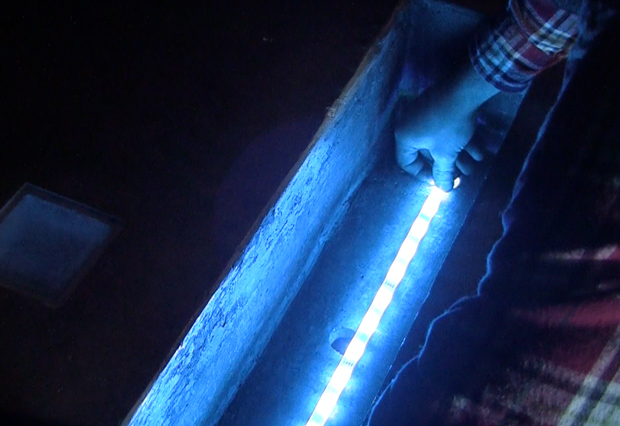

Insert your 16 foot LED strip light kit in the trough.

Run strip lighting under each coaster area.

Run strip lighting under each coaster area.

10. Fill the cooler with ice

10. Fill the cooler with ice

The trough is 36 inches long, 6 inches wide, and 7 inches deep. So it will hold plenty of beverages!

The trough is 36 inches long, 6 inches wide, and 7 inches deep. So it will hold plenty of beverages!

I made a cover for the cooler out of a piece of acrylic.

I made a cover for the cooler out of a piece of acrylic.

11. Party or host a barbecue!

11. Party or host a barbecue!

12. Please share this post, “Like”, and Pin!

12. Please share this post, “Like”, and Pin!

Sharing will help spread the word and will help make it possible for more free DIY Tutorials! Don't forget to sign up for the DIY PETE email list for free project tutorial updates and DIY inspiration! Click here to subscribe to my mailing list

Overall Process

Overall Process 2. Assemble the mold

2. Assemble the mold 3. Pour the concrete

3. Pour the concrete 5. Remove the mold and flip the table

5. Remove the mold and flip the table 6. Polish

6. Polish 7. Seal the concrete

7. Seal the concrete 8. Install top on a base

8. Install top on a base 10. Fill the cooler with ice

10. Fill the cooler with ice 11. Party or host a barbecue!

11. Party or host a barbecue! 13. Head over to

13. Head over to